An Unbiased View of Premier Aluminum Llc

An Unbiased View of Premier Aluminum Llc

Blog Article

Premier Aluminum Llc Things To Know Before You Get This

Table of ContentsPremier Aluminum Llc Things To Know Before You BuyThe Premier Aluminum Llc StatementsThe Premier Aluminum Llc StatementsThe Best Strategy To Use For Premier Aluminum Llc

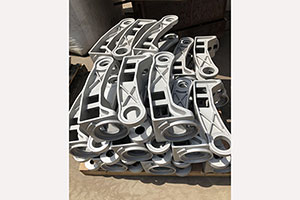

(https://www.reddit.com/user/premieraluminum/)Using low expense and unqualified providers can trigger high quality problems, and wasted time and money in the lengthy run. To aid you with the procedure, right here are some points to take into consideration when selecting the appropriate metal spreading supplier.

A firm that only uses the financial investment casting process will certainly attempt to sell you on why that procedure is best for your application (Casting Foundry). What if using the sand casting process is best for you and your demands? Rather, search for a distributor that offers a variety of casting procedures so the most effective alternative for YOU is picked

If collaborating with a solitary resource for all of your casting needs is crucial to you, the supplier needs to be diverse in its abilities. When integrated with various other incorporated capacities, this can aid streamline and compress the supply base. When selecting the best casting vendor, mindful factor to consider needs to be provided to quality, service, and rate.

The Definitive Guide for Premier Aluminum Llc

Customers increasingly select casting suppliers who have machining abilities. This can stay clear of conflict if flaws are uncovered during machining. If a 3rd party is machining, it may lead to "finger-pointing" about that is at fault. Is it a casting concern or a machining concern? If the spreading vendor uncovers a concern throughout machining, the trouble is resolved much faster with no conflict over whose fault it is.

What do you need from your spreading distributor? Are you looking for someone to simply deliver a metal part to your doorstep or do you require much more?

Some foundries are restricted or specialized. Make sure the supplier can meet all your product or alloy needs to get rid of the demand for several distributors.

Premier Aluminum Llc for Beginners

Study the supplier's web site. Talk to a sales associate or service affiliate.

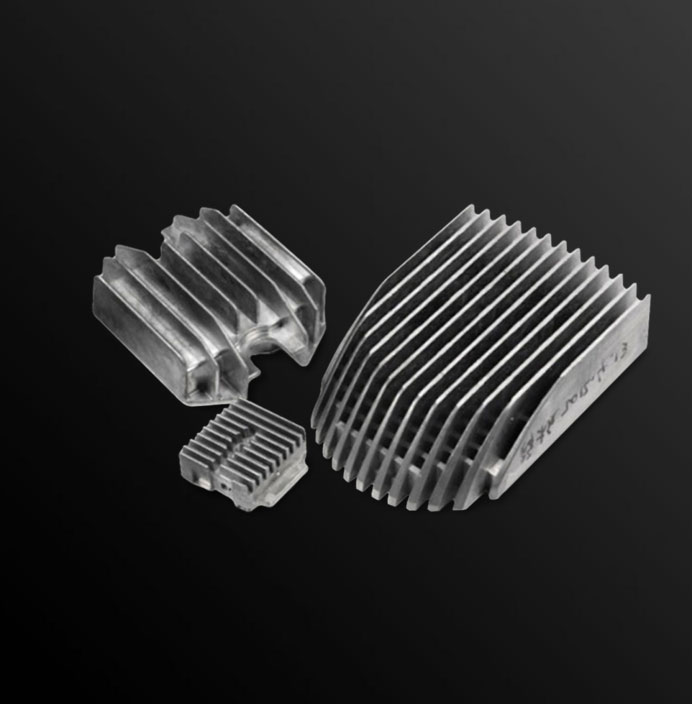

Aluminum is additionally light-weight and has good deterioration resistance, making it perfect for applications where weight and toughness are necessary variables. Additionally, light weight aluminum casting is an affordable method of manufacturing, as it requires less energy and resources than various other techniques. Iron casting, on the various other hand, involves putting liquified iron into a mold and mildew to produce a desired form.

Not known Facts About Premier Aluminum Llc

Iron spreading is likewise able to hold up against heats, making it ideal for usage in applications such as engine parts and commercial equipment. Iron casting can be a lot more pricey than light weight aluminum spreading due to the greater cost of raw products and the power required to thaw the iron. When determining in between aluminum casting and iron casting, it is very important to consider the certain requirements of the application.

In conclusion, both aluminum casting and iron casting have their own unique benefits and downsides. There are three sub-processes that drop under the category of die casting: gravity pass away spreading (or permanent mold casting), low-pressure die casting and high-pressure die casting. To obtain to the finished product, there are 3 key alloys made use of as die casting product to select from: zinc, light weight aluminum and magnesium. Report this page